|

Products |

|

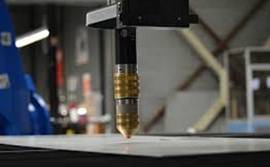

Thermal

plasma cutting machines are designed and built modular to ensure an optimum

quality / price. The

basic structure is made of special aluminum profiles and sealed linear axis

with ball screw or rack to ensure reliability, high precision, advances and

high DC

servomotors gives the car a high precision and advances of up to 10,000 mm /

min. Because of the closed loop tracking optics with no risk of loss of

position during processing and significantly reduces vibrations ensuring

quiet operation of the machine. Cutting

table is made of steel gratings, including hot dip galvanized water tank can

be used to reduce emissions of smoke and dust. The

CNC specialized for thermal cutting ensure precise cutting is suitable for

plasma cutting. It works independently and can store a number of programs

cut. Graphic LCD display allows manual programming, graphic simulation and

change the current program, scaling, setting parameters, etc. NCC ensure

automatic measurement of the distance to the plate, piercing remote plasma

generator specified by the manufacturer, maintaining and monitoring the

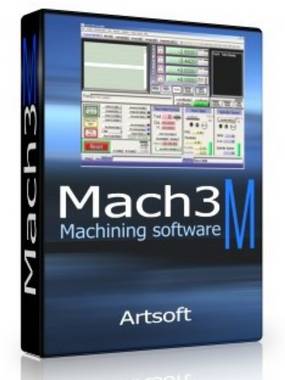

optimal distance between the plate and cutting head during processing. All CNC equipment Rolix products include a license SheetCam specialized software for automated functions debit thermal input I / O fabric, nesting, etc.. CNC cutting

equipment specialized equipment (net industrial) Design and execution Bucharest, industrial platform Republic include specialized software debit SheetCam (www.sheetcam.com) and mach3 Operating commands and design optimized for plasma cutting AC drive motors (servo motors) effective service (all electronic products in the country and permanently in stock) Software to optimize cutting (SheetCam) and generation (mach3) G code for cutting Import / export files in DXF, etc. the placement of inputs and outputs of material Table

guide: -

Technology for high precision plasma cutting -

Accuracy ฑ 0.1 mm Mechanical -

Positioning speed of axis: maximum 130 m / min, 8000mm / s -

Race X and Y is on precision linear guides (ISEL Germany) -

Cutting Table size: x = 3000mm. y = 1500mm or 3000mm 6000 * -

The flame height is adjusted during the race with ball screws tipped by

double linear guides -

Fast and accurate positioning with AC brushless servo motors type -

Y-axis: servo drive with double sync -

X axis: driving a single actuator -

Aza Z: screw ball by a single actuator -

Automatic cutting head height control (THC)

-

Windowsฎ CNC unit -

Automatic Programming -

Remote control with large tables Cutting table: -

Cutting table independently constructed of bridge and the car to maintain

accuracy under any load positioning table -

Cutting masses are stacked and can be moved independently of each other -

Cutting table for sheet metal with horizontal travel outside working surface

(2 pcs) -

Cutting table contains small parts tray recovery CNC plasma cutting system (Hypertherm):- Performanta

maximala de penetrare CNC: 25mm - Performanta

maximala de taiere (distanta pe minut): >4000mm/min la 3mm grosime

material - Amperi:

max60A - Circuit pilot

Dual-threshold - Circuit

Auto-voltage - Interfata CNC

standard

- Circuit pilot

Dual Threshold - Gun:

contact-start (arc ignition by contact) |